Away from the spotlight of empathetic chatbots and movie-like generated shorts, AI transforms the verticals where bits and atoms come together, at an accelerated pace.

In the world of industrial manufacturing, the last 50 years have been dominated by globalization – the transition of manufacturing to countries with lower salaries, alongside continuous supply chain optimization. If productivity couldn’t be increased (enough) through better technology, Excel data governance was there to save us.

But things are changing, and the latest technological developments, geopolitical trends, and Gen Z culture are accelerating a deep transformation of the manufacturing landscape.

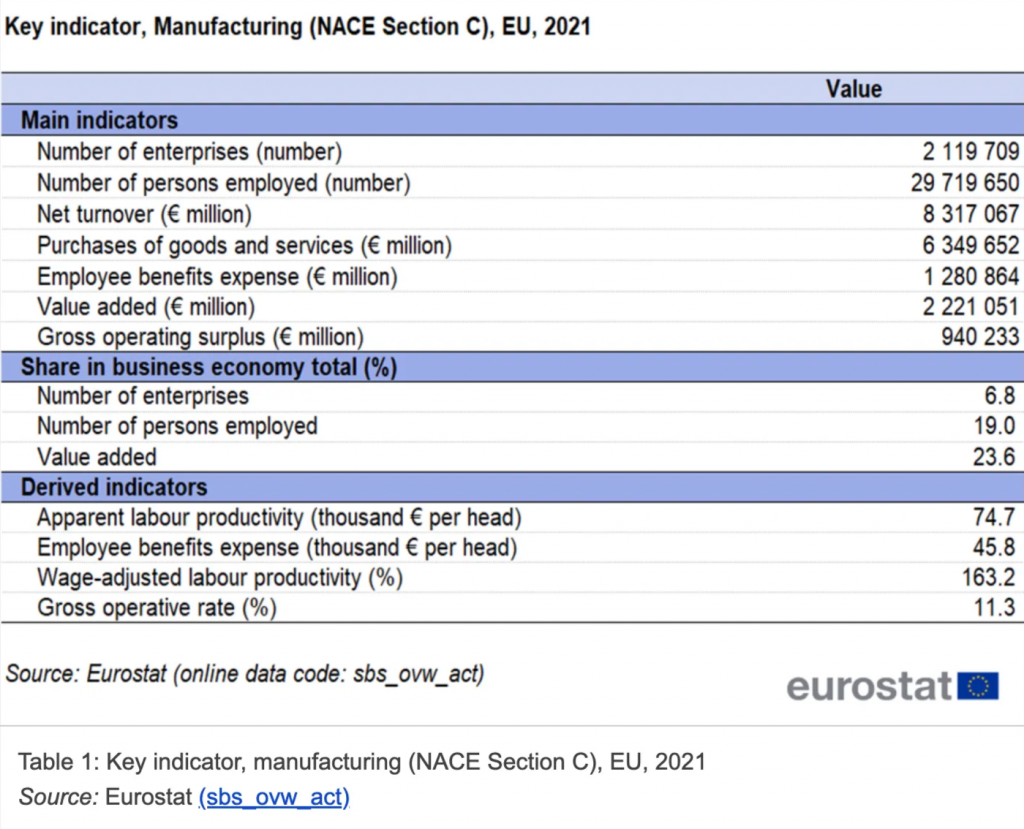

This is highly impactful. Manufacturing is one of the European Union’s key industries, with €8.3 trillion in net turnover and 28.7 million people employed in 2021 (as seen on Eurostat), representing 23.6% of the total value added of the EU’s economy.

Technology-wise, the latest AI developments allow for significant increases in automation and productivity. Wait, isn’t this already done?! Haven’t we all seen those robotic lines where cars are being welded together with minimum human involvement?

Yes and no. Such a level of automation works only for products’ niches manufactured for high-volume, highly standardized products, which means mostly electronics and automotive. In a 2019 study by AT Kearny, 72% of the manufacturing work was still carried out by manual manufacturing.

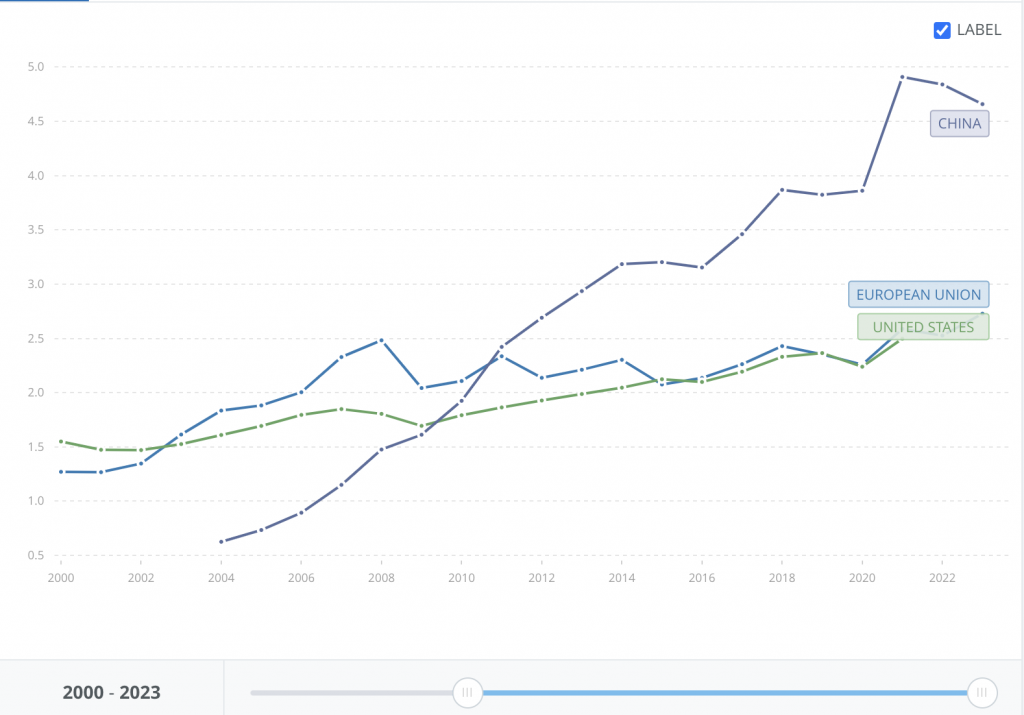

From a geopolitical point of view, the crisis of the last years has put manufacturing and supply chain processes under pressure. The pandemic years, Russia’s invasion of Ukraine, Red Sea terrorist activities, and the possibility of a Chinese invasion of Taiwan have impacted the predictability and costs of the global supply chain, creating the premises for the re-localization of industrial manufacturing in Europe and the US.

However, opening new manufacturing facilities also depends on the priorities of the next generation joining the workforce. The Gen Zs are a digital-first generation, very tech savvy, less inclined to do fieldwork, and less interested in working in manufacturing. A 2021 Deloitte study shows that by 2030, US manufacturing is expected to have 2.1 million unfilled jobs. And given the societal pressure, large-scale immigration does not look like a probable solution for many European countries and the US.

New technology meets market opportunity.

In 2024, we have connected with some of the best industrial tech founders, investors, and experts, and have identified some of the key use cases that are accelerating the transformation of industrial manufacturing: industrial co-pilots, digital twinning, intelligent automation, integrated factories, and autonomy.

Industrial co-pilots

Operating complex equipment can be difficult, especially for new employees or for infrequently used devices.

However, new co-pilots are helping employees to learn and adapt faster. You can have a quick conversation with the equipment, and ask it for the details you need, just like via the platform developed by Remberg (EU, €13M raised).

Digital twining

To apply any optimization algorithms, the physical world needs to have a digital representation that can be manipulated.

Systems for creating digital twins and optimizing the physical outcome are popping up in various areas of manufacturing or supply chain: Deltia.ai (EU, €6.1M raised) is helping optimize the manual manufacturing process, while Dexory (EU, $118M raised) is optimizing warehouse operations.

Intelligent automation

Manufacturing high-volume standardized products is fully automated. But lower-volume products, and/or products that need more customization, require a significant amount of manual work.

Companies like Intrinsic (US, owned by Alphabet), Wandelbots (EU, $122.2M raised), and Realtime Robotics (US, $71.5M raised) are helping engineers program and test robotic arms in faster cycles, adapting the manufacturing line to new products.

Integrated factories

Some startups, like Daedalus (EU, privately owned) or Hadrian (US, $216.5M raised), are coming up with a different solution to the same problem of fast adaptation of the manufacturing process. They fully automate the ordering and production processes, by building integrated factories for precision components.

Other emerging startups, like Cuby Technologies (US, $6.4M raised), aim to transform construction by deploying mobile micro-factories that build and assemble homes near-site without requiring skilled labor.

Autonomy

Some operations or processes can be entirely automated, using technologies that allow robots to react in real-time to the environment they operate in.

Anybotics (EU, $132M raised) builds legged robots that can inspect your industrial site and machinery, while Graymatter (US, $70.4M raised) builds autonomous robotic arms for sensitive processes, such as coating or polishing.

Vision-action-language models, such as the one developed by Wayve (UK, $1.3 billion raised), provide the technological basis for the next generation of autonomous industrial systems, while robotic foundational models, such as the ones being developed by Covariant.ai (US, $222M raised, founders hired by Amazon), help robots better understand the physical context in which they operate.

These technological developments paint an exciting picture. One in which industrial manufacturing tasks will be vastly automated and robots will be deployed for the most tedious, repetitive, and dangerous tasks. These developments will lead to more competition, higher efficiency, and more affordable and diverse products.

250 years ago, steam-powered engines started the industrial revolution. 150 years ago, electricity and the internal combustion engine enabled the 2nd industrial revolution. 50 years ago, computers brought the 3rd digital revolution.

Will AI bring the 4th industrial revolution? We have enough data points to be optimistic.

To the future!